Team

Cornell University Organic Robotics Laboratory, led by Rob Sheperd, in partnership with students at the University of Illinois Urbana-Champaign.

Role

I was the student lead on the Cornell side of this project, and my responsibility was to design the wing and the motor box to then be printed and sent to the University of Illinois lab for wind tunnel testing.

Challenge

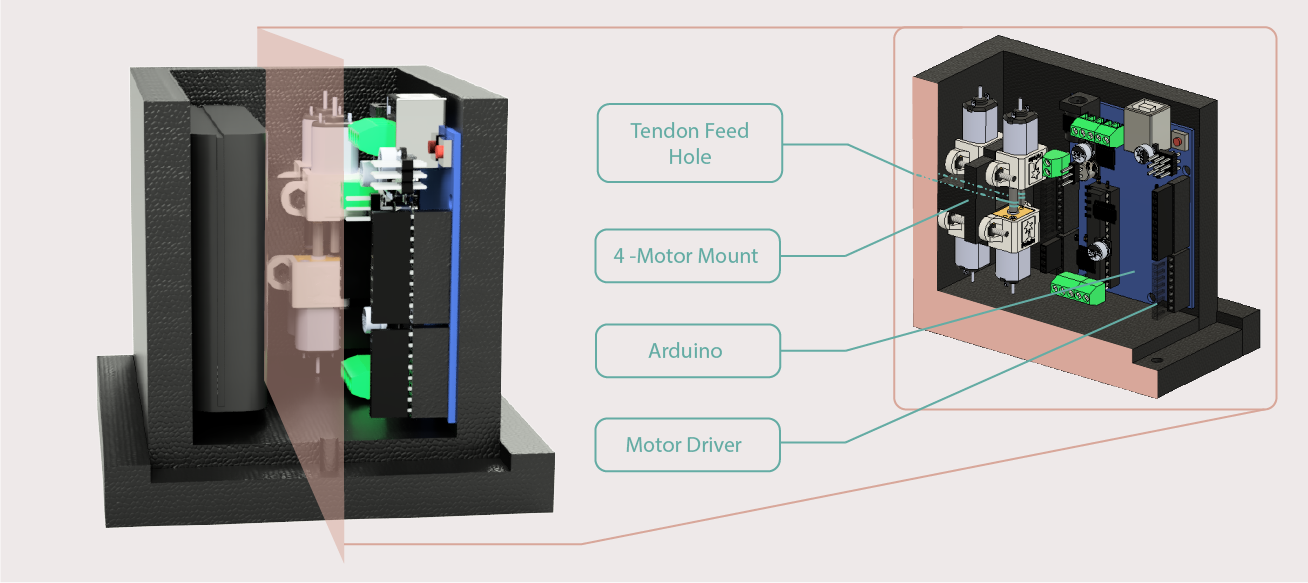

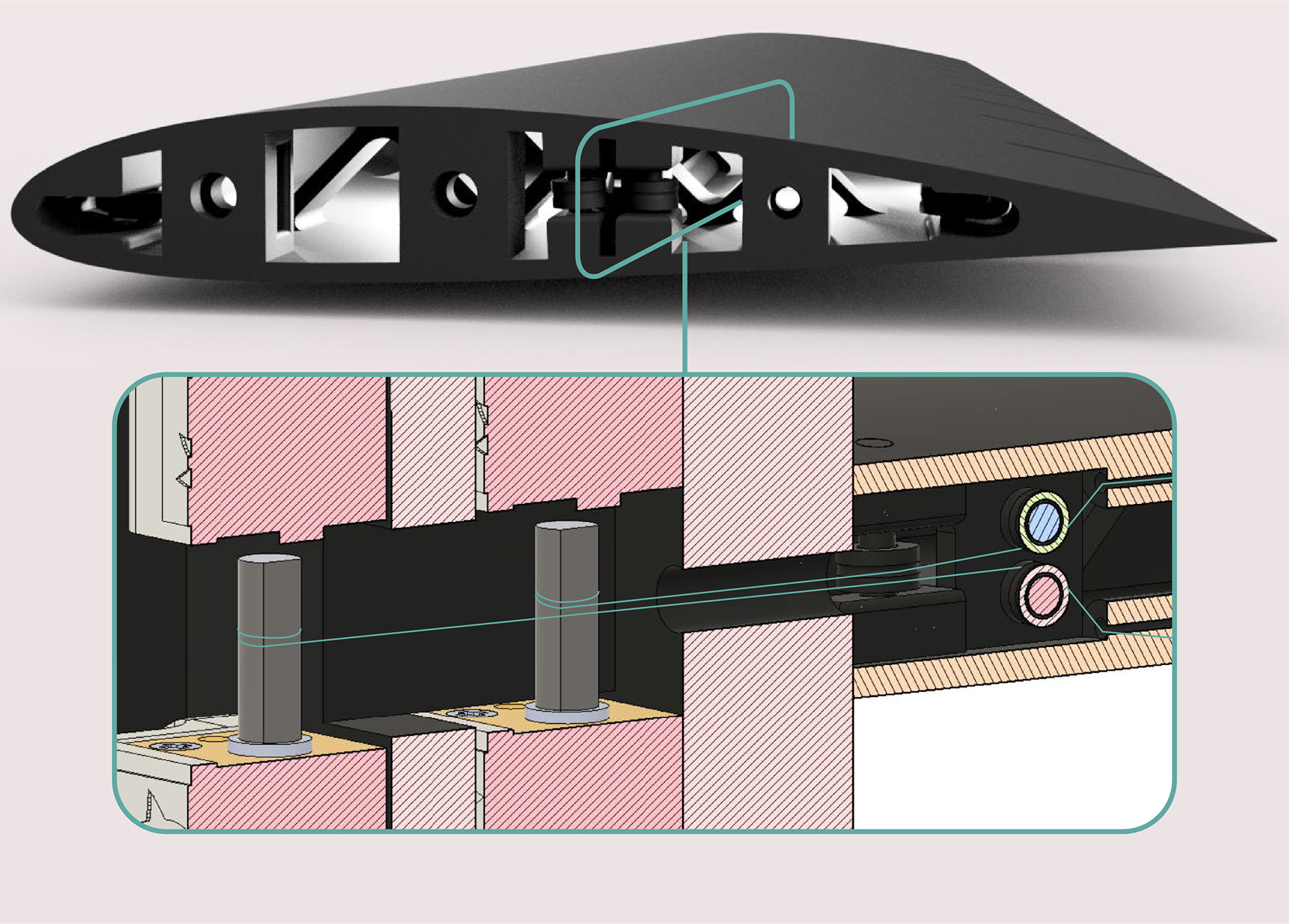

Creating a morphing wing as a single 3D-printed part turns out to be quite a challenge. This project was aimed toward creating a roughly ½-meter long, flexible NACA 2414 airfoil with 3 degrees of freedom controlled by tendons connected to a motor box

Approach

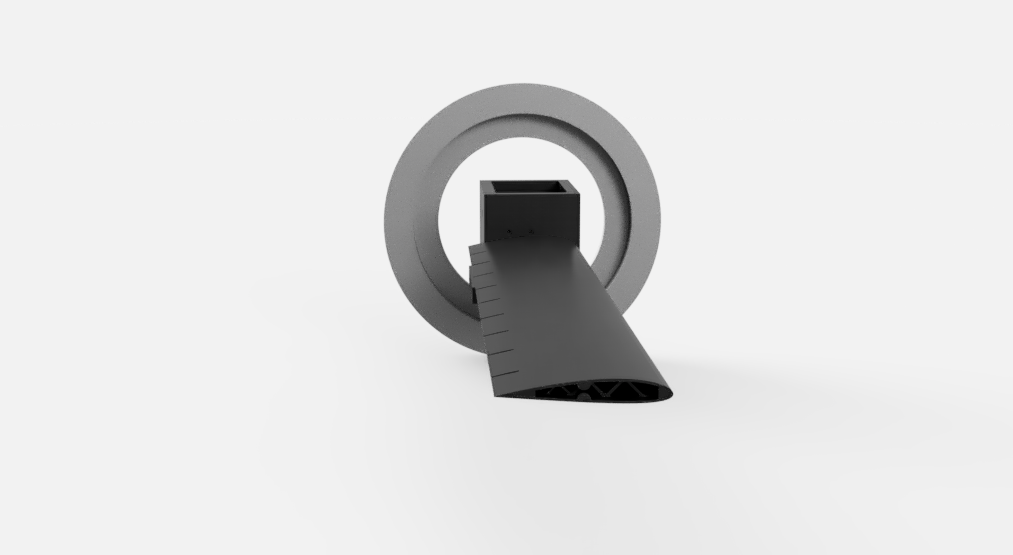

We went through many iterations of interior rib structures, shell thicknesses, and cutouts for flexibility, the changes throughout which were dictated by the capabilities of our Carbon printer and the achieved stiffness vs. flexibility. For our final model, we developed a diagonal rib support structure and a built-in pulley system to route the tendons through a single hole in the motor box.

______________________________________________________________________________

Learnings

I was able to improve my CAD skills greatly through this project, learning how to create complex parametric designs and assemblies with hundreds of joints. It has also been an exercise in balancing desired attributes, such as manufacturability and usability while fulfilling all design requirements. Since my partner throughout this project is a very creative thinker, he has also taught me both the ways in which he thinks through problems, as well as how to distill his ideas into designs that are practical while maintaining the necessary elements.